Burn-in

Burn-in

is an electrical stress test that employs

voltage

and

temperature

to accelerate the electrical failure of a device. Burn-in

essentially simulates the

operating

life

of the

device, since the electrical excitation applied during burn-in may

mirror the worst-case bias that the device will be subjected to in

the course of its useable life. Depending on the burn-in

duration

used, the reliability information obtained may pertain to the

device's

early

life

or its

wear-out.

Burn-in may be used as a

reliability monitor

or as a

production screen

to weed out potential

infant

mortalities from the lot.

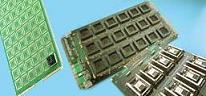

Burn-in

is usually done at

125 deg C,

with electrical excitation applied to the samples. The burn-in

process is facilitated by using

burn-in boards

(see Fig.

1) where the samples are loaded. These burn-in boards are then

inserted into the burn-in oven (see Fig. 2), which supplies the

necessary voltages to the samples while maintaining the oven

temperature at 125 deg C. The electrical bias applied may either be

static

or

dynamic,

depending on the failure mechanism being accelerated.

|

Figure 1. Photo of Bare and Socket-populated

Burn-in Boards |

The

operating life cycle distribution of a population of devices may be

modeled as a

bath tub

curve,

if the failures are plotted on the y-axis against the operating life

in the x-axis. The bath tub curve shows that the

highest

failure rates experienced by a population of devices occur during

the

early

stage of the life cycle, or early life, and during the

wear-out

period of the life cycle. Between the early life and wear-out

stages is a long period wherein the devices fail very sparingly.

Figure

2. Two examples of burn-in ovens

Early

life failure (ELF)

monitor burn-in, as the name implies, is performed to screen out

potential early life failures. It is conducted for a duration of 168

hours or less, and normally for only

48 hours.

Electrical failures after ELF monitor burn-in are known as early

life failures or infant mortality, which means that these units will

fail prematurely if they were used in their normal operation.

High Temperature Operating Life (HTOL)

Test is the opposite of ELF monitor

burn-in, testing the reliability of the samples in their wear-out

phase. HTOL is conducted for a duration of

1000 hours, with

intermediate read points at 168 H and 500 H.

Although

the electrical excitation applied to the samples are often defined

in terms of voltages, failure mechanisms accelerated by current

(such as electromigration) and electric fields (such as dielectric

rupture) are understandably accelerated by burn-in as well.